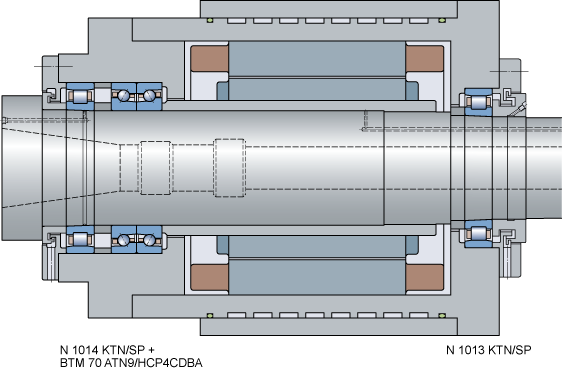

Lathe spindles are typically used to cut metals at relatively low speeds. Depth of cut and feed rates are usually pushed to the limit depending on the required surface finish. In a lathe, power is normally transmitted to the spindle by a pulley or gears, resulting in heavy radial loads at the non-tool end. On the tool end of the spindle, where there are heavy combined loads, a high degree of rigidity and high load carrying capacity are important operational requirements.